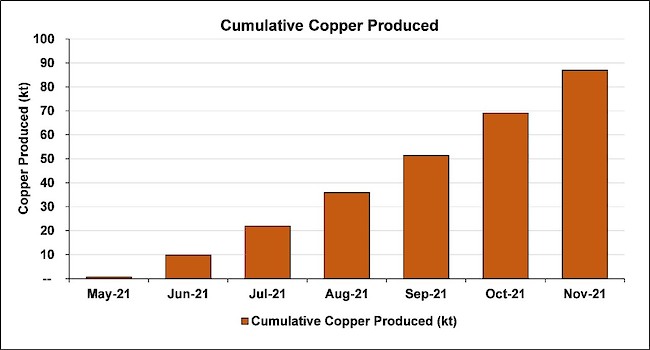

Record copper production in November tops 18,270 tonnes, bringing year-to-date production to more than 87,000 tonnes as at November 30, 2021

Earthworks commenced for a new box cut to access Phase 3 mining areas; Phase 3 concentrator targeted by end of 2024

Engineering for Kamoa Copper’s direct-to-blister smelter underway; long-lead items for smelter to be ordered in Q2 2022

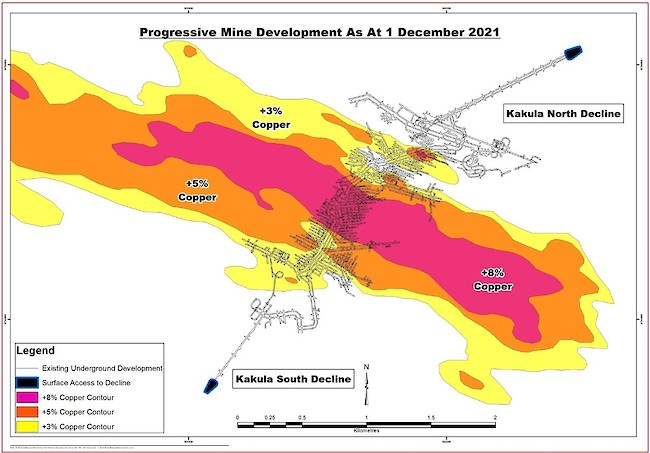

Mining crews deliver a record 548,000 tonnes of ore grading 5.46% copper in November, including 362,000 tonnes grading 6.60% copper from the centre of the Kakula Mine

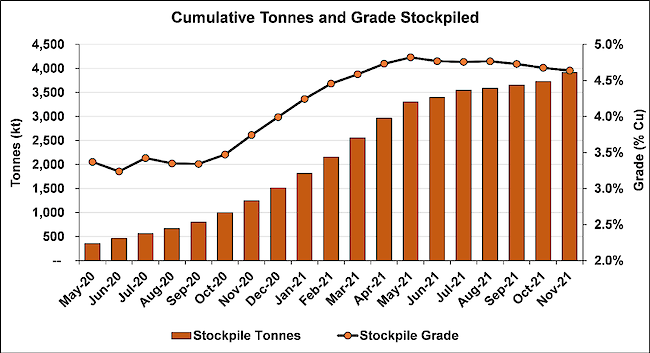

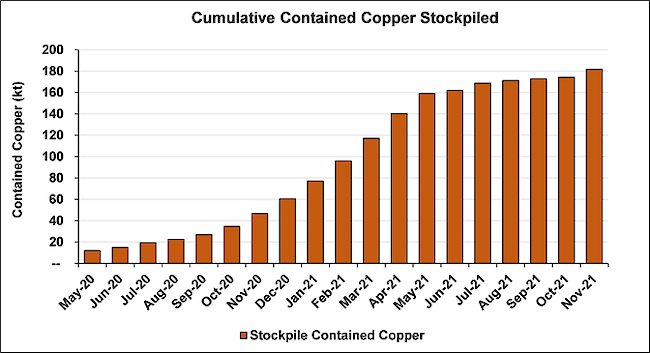

Record mining production in November increases surface stockpiles to 3.92 million tonnes grading 4.64% copper, containing more than 181,000 tonnes of copper

KOLWEZI, DEMOCRATIC REPUBLIC OF CONGO – Ivanhoe Mines (TSX: IVN; OTCQX: IVPAF) Co-Chairs Robert Friedland and Yufeng “Miles” Sun announced that Kamoa-Kakula’s Phase 2, 3.8 million-tonne-per-annum (Mtpa) concentrator plant now is approximately 70% complete and is well on track to begin operations in Q2 2022.

As the Phase 1, 3.8-Mtpa concentrator plant is operating at steady-state design capacity, further production updates will be provided only on a quarterly basis. Ivanhoe’s 2021 production guidance for contained copper in concentrate produced from Kamoa-Kakula’s Phase 1 concentrator is 92,500 to 100,000 tonnes. The higher guidance numbers are reinforced by an excellent production performance in November, which saw a record 18,270 tonnes of copper in concentrate produced, bringing year-to-date output to more than 87,000 tonnes as at November 30, 2021. The figures are on a 100%-project basis and metal reported in concentrate is prior to refining losses or deductions associated with smelter terms.

Watch the latest video showcasing the expansion work underway at the Kamoa Copper Complex:https://vimeo.com/654809393/8ca99b13e3

Kamoa-Kakula’s 2021 copper production to the end of the year, as well as guidance for 2022 copper production, cost of sales and cash costs, including the start of Phase 2 operations, will be provided in January 2022.

357,000 tonnes of ore were milled in November at an average feed grade of 6.18% copper, exceeding the monthly design run rate of 316,667 tonnes by more than 12%.

Copper flotation recoveries averaged 85.4% in November. The Phase 1, steady-state design copper recovery is approximately 86%, depending on ore feed grade.

Chart 1: Cumulative tonnes of copper produced May 2021 to November 30, 2021.

Construction of the second 3.8-Mtpa concentrator plant (Phase 2) continues to progress ahead of plan. Engineering, procurement and fabrication activities all are effectively complete. The main construction focus remains on the completion of structural steel erection and installation of platework, equipment and piping (SMPP). Electrical, control and instrumentation (EC&I) installation is advancing well, with numerous areas already handed over from the SMPP contractors to the EC&I contractors.

Both of the Phase 2 ball mills have been lifted into position and the girth gears installed. Installation of the lube system and pinion drive currently is underway. The final piece of major equipment for the Phase 2 concentrator plant, the high pressure grinding rolls (HPGR), has been lifted into position.

Electrical cable installation is advancing according to schedule. All the structural steel and platework, as well as the bulk of the piping, has been delivered to site. The last deliveries of piping are expected to arrive by mid-December. More than 580 truckloads of Phase 2 construction equipment and materials already have been delivered to site.

During November, the project’s construction team achieved 14.0 million fatality-free hours worked. This milestone underscores the strict safety culture of the Kamoa Copper construction team and contractors.

During its routine mass testing for new arrivals at the mine site, Kamoa Copper has recently identified a small number of COVID-19 infections. Any positive cases were quickly identified, isolated and treated, with cross contamination kept to a minimum, and there is no impact on operations. Kamoa also continues to focus intensively on rolling out vaccinations across the workforce and local communities. Maintaining this high standard of risk management remains a daily focus to prevent future cases.

Dr. Albert Odimboleko holding vials of Moderna and Pfizer vaccines used to vaccinate Kamoa Copper’s employees, contractors and local citizens.

Kamoa-Kakula’s adjacent Phase 1 and 2 concentrator plants.

Kamoa-Kakula’s Phase 1 (on the left) and Phase 2 ball mills.

Fitters Ren Xaioqi (left) and Lui Guang Jin cleaning the girth gear on the Phase 2 ball mills.

Installing the base plate for Phase 2’s high pressure grinding rolls (HPGR).

The Phase 2 HPGR being lifted into place.

One of two Phase 2 HPGR motors being lifted into place.

Crews lifting a section of piping into place for the Phase 2 concentrator.

Installation of new piping for the Phase 2 flotation cells is progressing quickly.

Laetitia Kyungu, a safety officer with T3 Projects DRC, at the Phase 2 plant. T3 Projects, a leading electrical contractor, has been providing electrical, control and instrumentation installation services for Kamoa-Kakula’s first two phases.

Mining crews produce a record 548,000 tonnes of ore in November as mining ramps up in advance of the Phase 2 concentrator start-up

A total of 548,000 tonnes grading 5.46% copper was mined during the period from October 21 to November 20, including 362,000 tonnes grading 6.60% copper from the Kakula Mine’s high-grade centre and 63,000 tonnes grading 3.61% copper from the Kansoko Mine.

Mark Farren, CEO of Kamoa Copper, commented: “548,000 tonnes of ore mined is a major increase compared to our previous monthly record of 409,000 tonnes mined. We expect to see continued growth in monthly mine production as we introduce additional mining crews to fill the second concentrator. We remain firmly on track to start the Phase 2 concentrator production in Q2 2022.”

Production was boosted by the arrival of a new mining equipment supplied by Sandvik of Stockholm, Sweden. The new equipment is being used to ramp up mining operations in advance of the start of the Phase 2 concentrator plant.

The inflow of water from the water-bearing structure intersected in October at Kakula’s northern perimeter drift was brought under control in early November, and normal mining operations have resumed in the area.

The project’s surface stockpiles now contain approximately 3.92 million tonnes of high-grade and medium-grade ore at an estimated, blended average of 4.64% copper. Contained copper in the stockpiles at the end of November now totals more than 181,000 tonnes (the current copper price is approximately US$9,600 per tonne).

Chart 2: Cumulative tonnes and grade of ore stockpiles at the Kakula and Kansoko mines – May 2020 to November 2021.

Chart 3: Growth in contained copper in ore stockpiles at the Kakula and Kansoko mines – May 2020 to November 2021.

Kamoa-Kakula’s Phase 1 and 2 concentrator plants and the ore stockpiles at the Kakula northern declines. The blended stockpiles currently contain approximately 1.98 million tonnes grading 5.08% copper.

The Kakula southern decline and ore stockpiles containing a combined 1.32 million tonnes grading 4.34% copper (consisting of 465,000 high-grade tonnes @ 6.09% copper and 853,000 medium-grade tonnes @ 3.39% copper).

The Kansoko decline and ore stockpiles containing a combined 619,000 tonnes grading 3.86% copper (consisting of 194,000 high-grade tonnes @ 5.60% copper and 425,000 medium-grade tonnes @ 3.07% copper).

Figure 1: Underground development completed at Kakula Mine to December 1, 2021 (in black).

Kamoa-Kakula is projected to be the world’s highest-grade major copper mine, with an initial mining rate of 3.8 Mtpa at an estimated, average feed grade of more than 6.0% copper over the first five years of operations, and 5.9% copper over the initial 10 years of operations. Phase 1 is expected to produce approximately 200,000 tonnes of copper per year, while the Phase 2 expansion is forecast to increase production to approximately 400,000 tonnes of copper annually. Based on independent benchmarking, the project’s phased expansion scenario to 19 Mtpa would position Kamoa-Kakula as the world’s second-largest copper mining complex, with peak annual copper production of more than 800,000 tonnes.

The Kamoa-Kakula Copper Project is a joint venture between Ivanhoe Mines (39.6%), Zijin Mining Group (39.6%), Crystal River Global Limited (0.8%) and the Government of the Democratic Republic of Congo (DRC) (20%). A 2020 independent audit of Kamoa-Kakula’s greenhouse gas intensity metrics performed by Hatch Ltd. of Mississauga, Canada, confirmed that the project will be among the world’s lowest greenhouse gas emitters per unit of copper produced.

Electricians Richard Onkarabetse Keetile (left), and Khris Mpanda Ilunga inspecting electrical control panels for a newly-installed, underground pumping station at the Kansoko Mine.

Study work for Phase 3 expansion advancing; excavation underway on a new box cut (Kamoa Mine decline) to open up the Kamoa mining footprint

The scope of Kamoa-Kakula’s Phase 3 expansion includes a third concentrator plant to be located adjacent to the Kansoko Mine (at the Kansoko Sud orebody), approximately 10 kilometres north of the Kakula Mine. The Phase 3 concentrator is being designed to have a larger nameplate milling capacity than the 3.8-Mtpa nameplate milling capacity of the Phase 1 and 2 concentrators.

The planned Phase 3 concentrator is expected to be supplied by ore from the established mine at Kansoko, as well as from two new planned mines, named Kamoa 1 and Kamoa 2. The Kamoa 1 and Kamoa 2 mining areas will be accessed via a twin-decline system (the Kamoa Mine decline) which now is under construction.

Phase 3 also includes the upgrade of turbine 5 at the Inga II hydropower complex to provide an additional 162 megawatts (MW) of renewable hydropower, and the construction of a direct-to-blister smelter, with a production capacity of 500,000 tonnes per annum of blister copper. On November 18, 2021, Kamoa Copper awarded China Nerin Engineering Co., Ltd. of Jiangxi, China, with the basic engineering contract for the smelter that will incorporate leading-edge technology supplied by Metso Outotec of Espoo, Finland.

The planned smelter is to be built adjacent to the Phase 1 and Phase 2 concentrator plants, and is designed to meet the International Finance Corporation’s emissions standards. The smelter has been sized to process the majority of the copper concentrate forecast to be produced by Kamoa-Kakula’s Phase 1, Phase 2 and Phase 3 concentrators. With a nameplate capacity of 500,000 tonnes per annum of blister copper, it is projected to be one of the largest, single-line blister-copper flash smelters in the world, and the largest in Africa. The next stages of project development will be the completion of basic engineering and the ordering of the long-lead items of equipment.

Study work on all aspects of the Phase 3 expansion is progressing well, with expected completion in Q2 2022, after which Kamoa Copper will advance into a more detailed phase of design and engineering work.

Mr. Farren noted: “We have made excellent progress on determining the best location of the new box cut that will be able to serve both the Kamoa 1 and Kamoa 2 mines from the same infrastructure. Geotechnical and hydrological work is almost complete for the decline system and earthworks began on the box cut on December 2, 2021.

“While we are in the process of refining the mine design and scheduling of the planned new mines at the Kamoa orebody, we believe that Phase 3 production could boost Kamoa-Kakula to become among the very largest copper mines. Phase 3 will include maximizing the potential of both the Phase 1 and 2 concentrators, as well as construction of a new, larger concentrator at the Kamoa Mine.

“We expect to start up the Phase 3 concentrator by the end of 2024. This timing is aligned with our Inga 2 hydropower project, where we expect to complete the refurbishment of the 162-megawatt turbine 5 in Q4 2024.”

Kamoa Copper’s management team and machine operators celebrating the commencement of earthworks and excavation of the Kamoa 1 box cut

Earthworks now underway for the box cut for the Kamoa 1 decline.

Aerial view of the Kamoa-Kakula Copper Complex. The planned smelter is to be built within the area outlined in red, adjacent to the Phase 1 and 2 concentrators (in yellow circle).

Kamoa Copper’s green energy focus now on the Inga II hydropower plant as a source of additional clean electricity to power Kamoa-Kakula expansions

In August 2021, Kamoa-Kakula’s energy company signed an extension of the existing financing agreement with the DRC’s state-owned power company SNEL to upgrade turbine 5 at the Inga II hydropower complex. Since June 2021, rehabilitation scoping works and technical visits have been conducted by Stucky Ltd. of Renens, Switzerland, and Voith Hydro of Heidenheim, Germany, a leading engineering group. Voith Hydro, the contractor for the turbine 5 upgrade, has successfully rehabilitated two turbine generators at the adjoining Inga I hydropower plant, a project that was financed by the World Bank.

Turbine 5 is expected to produce 162 MW of renewable hydropower, providing the Kamoa-Kakula Copper Complex and the planned, associated smelter with abundant, sustainable electricity for future expansions. Early works related to the removal of sand from the area around turbine 5 is nearing completion, which will allow the engineering team to complete the scoping work. Dismantling of turbine 5, starting on the alternator level, has commenced. Basic engineering for the design of a new turbine wheel and runners is ongoing at Voith’s Heidenheim offices.

The substation at the Inga II hydropower facility, alongside the Inga River.

Kamoa Copper and Ivanhoe Mines senior management teams with auditors from international accounting firm PwC at one of the high-grade mining areas at the Kakula Mine.

Landscaper Jenny Mutimpa LeDoux working in the gardens at Kamoa village.

Kona Mumongo Grace, a farmer in the village of Kaponda, and his daughter Tshisola, with tangerine orange tree seedlings for planting at his home. The seedlings were among 3,200 donated by the Kamoa-Kakula Sustainable Livelihoods Program to promote sustainable development in local communities.

Qualified Persons

Disclosures of a scientific or technical nature regarding development scenarios at the Kamoa-Kakula Project in this news release have been reviewed and approved by Steve Amos, who is considered, by virtue of his education, experience and professional association, a Qualified Person under the terms of NI 43-101. Mr. Amos is not considered independent under NI 43-101 as he is Kamoa Copper’s Head of Projects. Mr. Amos has verified the technical data disclosed in this news release.

Other disclosures of a scientific or technical nature regarding the stockpiles in this news release have been reviewed and approved by George Gilchrist, who is considered, by virtue of his education, experience and professional association, a Qualified Person under the terms of NI 43-101. Mr. Gilchrist is not considered independent under NI 43-101 as he is the Vice President, Resources of Ivanhoe Mines. Mr. Gilchrist has verified the other technical data related to the stockpiles disclosed in this news release.

The stockpile grade estimates contained in this release are based upon bulk ore sampling from material being fed to the plant from surface stockpiles, and underground vertical channel sample profiles from recent development. Channel sample profiles are cut approximately 15 metres apart in 1-metre vertical increments across the full vertical exposure using a handheld grinder, with a 100-to-150-gram sample collected. The samples are pulverized at the project’s onsite laboratory and analyzed using a portable XRF (pXRF) instrument. Kamoa Copper has routinely analyzed its exploration drill core for copper using pXRF, in addition to analysis at a commercial laboratory using four acid digest and ICP-OES. This data has demonstrated that pXRF results can be relied upon for grade control and run-of-mine sampling. Due to rounding, numbers presented throughout this news release may not add up precisely.

Ivanhoe has prepared an independent, NI 43-101-compliant technical report for the Kamoa-Kakula Project, which is available on the company’s website and under the company’s SEDAR profile at www.sedar.com:

- Kamoa-Kakula Integrated Development Plan 2020 dated October 13, 2020, prepared by OreWin Pty Ltd., China Nerin Engineering Co., Ltd., DRA Global, Epoch Resources, Golder Associates Africa, KGHM Cuprum R&D Centre Ltd., Outotec Oyj, Paterson and Cooke, Stantec Consulting International LLC, SRK Consulting Inc., and Wood plc.

The technical report includes relevant information regarding the assumptions, parameters and methods of the mineral resource estimates on the Kamoa-Kakula Project cited in this news release, as well as information regarding data verification, exploration procedures and other matters relevant to the scientific and technical disclosure contained in this news release.

About Ivanhoe Mines

Ivanhoe Mines is a Canadian mining company focused on advancing its three principal projects in Southern Africa: the development of major new, mechanized, underground mines at the Kamoa-Kakula copper joint-venture in the Democratic Republic of Congo and at the Platreef palladium-rhodium-platinum-nickel-copper-gold discovery in South Africa; and the extensive redevelopment and upgrading of the historic Kipushi zinc-copper-germanium-silver mine, also in the Democratic Republic of Congo.

Kamoa-Kakula began producing copper concentrates in May 2021 and, through phased expansions, is positioned to become one of the world’s largest copper producers. Kamoa-Kakula is being powered by clean, renewable hydro-generated electricity and is projected to be among the world’s lowest greenhouse gas emitters per unit of metal produced. Ivanhoe Mines has pledged to achieve net-zero operational greenhouse gas emissions (Scope 1 and 2) at the Kamoa-Kakula Copper Mine. Ivanhoe also is exploring for new copper discoveries on its Western Foreland exploration licences in the Democratic Republic of Congo, near the Kamoa-Kakula Project.

Information contacts

Investors: Bill Trenaman +1.604.331.9834 / Media: Matthew Keevil +1.604.558.1034

Forward-looking statements

Certain statements in this release constitute “forward-looking statements” or “forward-looking information” within the meaning of applicable securities laws. Such statements and information involve known and unknown risks, uncertainties and other factors that may cause the actual results, performance or achievements of the company, its projects, or industry results, to be materially different from any future results, performance or achievements expressed or implied by such forward-looking statements or information. Such statements can be identified by the use of words such as “may”, “would”, “could”, “will”, “intend”, “expect”, “believe”, “plan”, “anticipate”, “estimate”, “scheduled”, “forecast”, “predict” and other similar terminology, or state that certain actions, events or results “may”, “could”, “would”, “might” or “will” be taken, occur or be achieved. These statements reflect the company’s current expectations regarding future events, performance and results and speak only as of the date of this release.

Such statements include without limitation, the timing and results of: (i) statements regarding Ivanhoe’s guidance for contained copper in concentrate expected to be produced by Kamoa-Kakula for 2021 has been increased to between 90,000 to 95,000 tonnes; (ii) statements regarding the expectation that the Phase 2 concentrator is expected to begin operations in Q2 2022; (iii) statements regarding Kakula is projected to be the world’s highest-grade major copper mine, with an initial mining rate of 3.8 Mtpa at an estimated, average feed grade of more than 6.0% copper over the first five years of operations and 5.9% copper over the initial 10 years of operations; (iv) statements regarding Kamoa-Kakula’s Phase 1 is expected to produce approximately 200,000 tonnes of copper per year, and Phases 1 and 2 combined are forecast to produce approximately 400,000 tonnes of copper per year; (v) statements regarding based on independent benchmarking, the project’s phased expansion scenario to 19 Mtpa would position Kamoa-Kakula as the world’s second largest copper mining complex, with peak annual copper production of more than 800,000 tonnes; (vi) statements regarding Kamoa-Kakula will be among the world’s lowest greenhouse gas emitters per unit of copper produced; (vii) statements regarding that Phase 3 production could boost Kamoa-Kakula’s to become among the very largest copper mines; (viii) statements regarding the expectation to start up the Phase 3 concentrator by the end of 2024; (ix) statements regarding the expectation to complete the refurbishment of the 162-megawatt turbine 5 in Q4 2024; and (x) statements regarding the expectation to complete study work on all aspects of the Phase 3 expansion in Q2 2022.

As well, all of the results of the Kakula definitive feasibility study, the Kakula-Kansoko pre-feasibility study and the Kamoa-Kakula preliminary economic assessment, constitute forward-looking statements or information, and include future estimates of internal rates of return, net present value, future production, estimates of cash cost, proposed mining plans and methods, mine life estimates, cash flow forecasts, metal recoveries, estimates of capital and operating costs and the size and timing of phased development of the projects. Furthermore, with respect to this specific forward-looking information concerning the development of the Kamoa-Kakula Project, the company has based its assumptions and analysis on certain factors that are inherently uncertain. Uncertainties include: (i) the adequacy of infrastructure; (ii) geological characteristics; (iii) metallurgical characteristics of the mineralization; (iv) the ability to develop adequate processing capacity; (v) the price of copper; (vi) the availability of equipment and facilities necessary to complete development; (vii) the cost of consumables and mining and processing equipment; (viii) unforeseen technological and engineering problems; (ix) accidents or acts of sabotage or terrorism; (x) currency fluctuations; (xi) changes in regulations; (xii) the compliance by joint venture partners with terms of agreements; (xiii) the availability and productivity of skilled labour; (xiv) the regulation of the mining industry by various governmental agencies; (xv) the ability to raise sufficient capital to develop such projects; (xvi) changes in project scope or design; (xvii) political factors; (xviii) unforeseen delays or stoppages in shipping and transportation of goods and equipment; (xix) water inflow into the mine and its potential effect on mining operations; and (xx) the consistency and availability of electric power.

Forward-looking statements and information involve significant risks and uncertainties, should not be read as guarantees of future performance or results and will not necessarily be accurate indicators of whether or not such results will be achieved. A number of factors could cause actual results to differ materially from the results discussed in the forward-looking statements or information, including, but not limited to, the factors discussed below and under “Risk Factors”, and elsewhere in this release, as well as unexpected changes in laws, rules or regulations, or their enforcement by applicable authorities; the failure of parties to contracts with the company to perform as agreed; social or labour unrest; changes in commodity prices; and the failure of exploration programs or studies to deliver anticipated results or results that would justify and support continued exploration, studies, development or operations.

Although the forward-looking statements contained in this release are based upon what management of the company believes are reasonable assumptions, the company cannot assure investors that actual results will be consistent with these forward-looking statements. These forward-looking statements are made as of the date of this release and are expressly qualified in their entirety by this cautionary statement. Subject to applicable securities laws, the company does not assume any obligation to update or revise the forward-looking statements contained herein to reflect events or circumstances occurring after the date of this release.

The company’s actual results could differ materially from those anticipated in these forward-looking statements as a result of the factors set forth below in the “Risk Factors” section in the company’s 2021 Q3 MD&A and its current annual information form.

English

English Français

Français 日本語

日本語 中文

中文