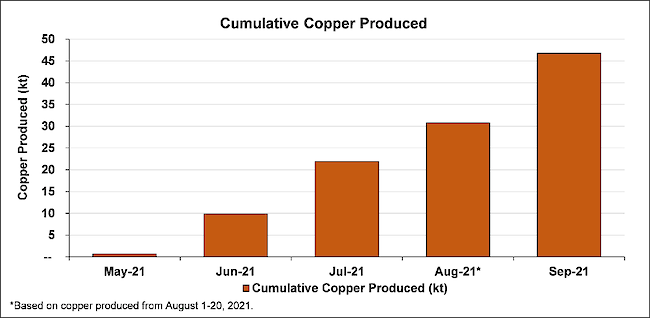

A record 16,010 tonnes of copper produced in the month ended September 20

More than 46,750 tonnes of copper produced year-to-date to September 20

2021 production guidance range for copper in concentrate raised to 85,000 to 95,000 tonnes

Floated concentrate grade improved to 55.7% copper; average plant flotation recovery increased to 85.1%; both nearing nameplate design

Phase 2 concentrator construction now more than 50% complete

Mining crews delivered 384,000 tonnes of ore grading 5.58% copper in September, including 141,000 tonnes grading 7.32% copper from the centre of the Kakula Mine

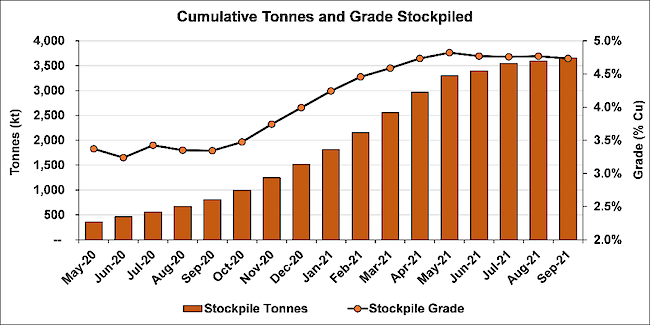

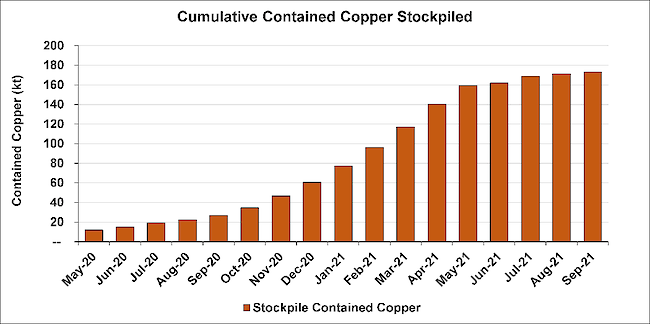

Surface ore stockpiles continue to grow; now hold 3.66 million tonnes grading 4.73% copper, containing more than 173,000 tonnes of copper

KOLWEZI, DEMOCRATIC REPUBLIC OF CONGO – Ivanhoe Mines (TSX: IVN; OTCQX: IVPAF) Co-Chairs Robert Friedland and Yufeng “Miles” Sun announced that ramp-up of Kamoa-Kakula’s Phase 1, 3.8 million-tonne-per-annum (Mtpa) concentrator plant continues to advance ahead of schedule, with 319,795 tonnes of ore milled in September, exceeding the monthly design run rate of 316,667 tonnes at an average feed grade of 6.0% copper.

A total of 16,010 tonnes of copper in concentrate were produced (filtered product) and a total of 16,503 tonnes floated in the reporting month ended September 20th – Kamoa Copper’s fourth full month of production – establishing a new monthly record and nearing the Phase 1 target output of 16,666 tonnes per month, or 200,000 tonnes per annum. The difference between filtered and floated copper is approximately 500 tonnes in inventory in the concentrate thickener and the filter feed tank.

The average floated concentrate copper grade in September improved to 55.7%, up from approximately 48% in August. A total of 46,764 tonnes of copper in concentrate had been produced year-to-date as of September 20, 2021, for delivery to either the Lualaba Copper Smelter near Kolwezi, or to international markets.

Copper flotation recoveries improved to an average of 85.1% during September, up from an average of 83% during August. The Phase 1, steady-state-design copper recovery is approximately 86%, depending on ore feed grade.

A daily record copper recovery of 88.3% was achieved on September 12th and a daily floated copper production of 721 tonnes was achieved on September 15th. Subsequent to the reporting period, a daily milling record of 12,596 tonnes and a daily crushing record of 14,778 tonnes were achieved on September 27th.

Chart 1: Cumulative tonnes of copper produced May 2021 to September 20, 2021.The August total has been adjusted to reflect cumulative copper produced to August 20, 2021 (the new monthly reporting cut-off date).

Mark Farren, Kamoa Copper’s CEO, commented on September’s operating performance: “The Kamoa-Kakula team has worked tirelessly to bring the Phase 1 concentrator to steady-state performance. We are very pleased with the September results, where we exceeded steady-state design parameters for ore throughput and were close to achieving steady-state design copper recovery and monthly copper production.

“There are a number of additional adjustments being incorporated into the Phase 1 processing circuit, which will enable the concentrator to achieve better results in the next quarter. These adjustments, which also will be incorporated into the Phase 2 processing circuit, should position us to achieve 2021 copper production in the upper end of our previous guidance of 80,000 to 95,000 tonnes. This gives us the confidence to raise the range to 85,000 to 95,000 tonnes.

“Mining production was steady at 384,000 tonnes produced from the Kakula and Kansoko mines. The mining teams now are well established and are able to consistently outperform our internal budget. We have established a solid base of skilled and motivated Congolese workers, who no doubt will carry us through the ramp-up of Phase 2 and subsequent expansions of our mining footprint. It also is encouraging to note that the Phase 2 concentrator construction remains solidly ahead of schedule and on budget.”

Ivanhoe’s production guidance for contained copper in concentrate at Kamoa-Kakula in 2021 has been raised to 85,000 to 95,000 tonnes. The figures are on a 100%-project basis and metal reported in concentrate is prior to refining losses or deductions associated with smelter terms. The guidance assumes ramp-up continues in line with published technical disclosures.

Performance guarantee tests were successfully completed on the Phase 1 concentrator plant during the first three days of September. The performance tests involved a 72-hour continuous run at steady-state design, or above, ore throughput and grind.

Kamoa-Kakula is fast tracking the commissioning of an additional concentrate filter, which has been installed alongside the Phase 1 filter, to be able to take advantage of copper feed grades and milling rates in excess of design parameters. The additional concentrate filter is expected to be fully operational in early October 2021, enabling the Phase 1 concentrator to produce more copper than its design capacity of approximately 200,000 tonnes per year.

Watch a new video showcasing the ramp-up of copper production at Kamoa-Kakula and the production of blister copper at the local Lualaba Copper Smelter: https://vimeo.com/618907781/0e2fd0ca11

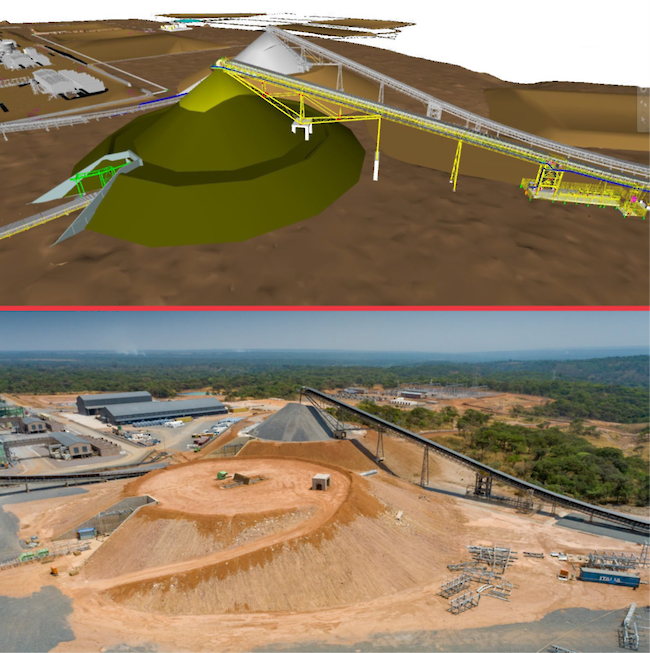

Phase 2 concentrator plant overall construction more than 50% complete, with the current focus on structural steel, mechanical, piping and platework (SMPP) erection and installation

Construction of the second 3.8-Mtpa concentrator plant (Phase 2) is progressing well, with the overall project more than 50% complete; engineering and procurement activities are effectively complete with fabrication at 86% complete. Civil construction works also are effectively complete, with the focus now on erection of structural steel and the installation of platework and equipment. A 400-tonne crane (the largest in the DRC) has arrived on site and has been used to lift the tailings thickener rake into position. The crane also will shortly be used to install the ball mills, the ball mill shells, girth gear and ball mill ends, all of which are on site.

The bulk of the 2,193 tonnes of structural steel and the 570 tonnes of platework is on site and the bulk of the 18,644 metres of piping is en route to site. The six-kilometre tailings return water piping has been delivered to site and installation is nearing completion. More than 418 truckloads of Phase 2 construction equipment and materials already have been delivered to site and another 49 truckloads are en-route. The Phase 2 concentrator remains on track for completion in Q3 2022.

Commissioning of the Phase 1 backfill is advancing well with C4 (hot commissioning) activities. More than 7,250 cubic metres of paste backfill have been pumped to an underground trial stope in the Kakula Mine.

The two time-lapsed videos below highlight Kamoa-Kakula’s Phase 2 construction efforts, including lifting the ball mills, flotation cells and the tailings thickener.

Video 1: https://vimeo.com/616144971/c0c90f41cf

Video 2: https://vimeo.com/616147092/a718a29b98

Installation of the Phase 2 ball mills is advancing quickly.

The first six flotation cells for the Phase 2 concentrator have been installed, with installation of the Phase 2 ball mills underway in the background.

Members of the construction team with a section of a Phase 2 ball mill shell.

Lifting the Phase 2 secondary screen pan feeder into place.

Mechanic Kabuanga Clement installing a safety railing inside the Phase 2 high-pressure-grinding-rolls (HPGR) stockpile tunnel.

Nadege Santos, Construction Secretary (left), and Doralie Kona, Construction Engineer in training, at the Phase 2 concentrator plant.

A 3D rendering of the Phase 2 flotation cells under construction alongside the Phase 1 flotation cells. The picture below shows current construction progress of the Phase 2 cells, which is 52% complete.

A 3D rendering of the Phase 2 high-pressure-grinding-rolls (HPGR) plant under construction alongside the operating Phase 1 HPGR plant. The picture below shows current construction progress of the Phase 2 plant, which is 54% complete.

A 3D rendering of the Phase 2 high-pressure-grinding-rolls (HPGR) plant under construction alongside the operating Phase 1 HPGR plant. The picture below shows current construction progress of the Phase 2 plant, which is 71% complete.

Mining continues ahead of schedule, adding to the surface ore stockpiles

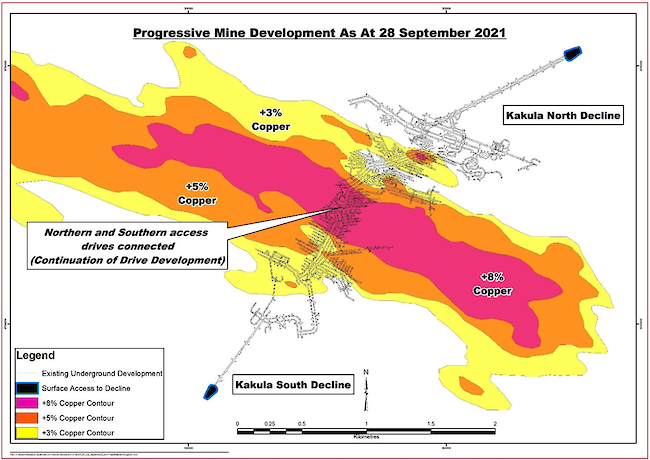

A total of 384,000 tonnes grading 5.58% copper was mined during the period from August 21 to September 20, including 141,000 tonnes grading 7.32% copper from the Kakula Mine’s high-grade centre and 36,000 tonnes grading 4.89% copper from the Kansoko Mine.

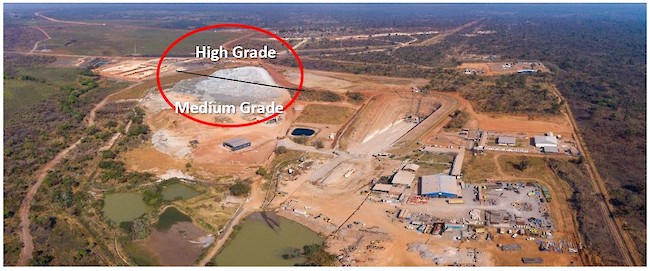

The project’s surface stockpiles now contain approximately 3.66 million tonnes of high-grade and medium-grade ore at an estimated, blended average of 4.73% copper. Contained copper in the stockpiles at the end of August now totals more than 173,000 tonnes (the current copper price is approximately US$9,200 per tonne).

In September, crews began transporting high-grade ore from the surface stockpile near the Kakula southern decline directly to the Phase 1 concentrator plant or to the main surface stockpiles near the Kakula northern decline.

Chart 2: Cumulative tonnes and grade of ore stockpiles at the Kakula and Kansoko mines – May 2020 to September 2021.

Chart 3: Growth in contained copper in ore stockpiles at the Kakula and Kansoko mines – May 2020 to September 2021.

The Kakula Mine, concentrator plants and main ore stockpiles at Kakula’s northern declines (in red circle). The blended stockpiles currently contain approximately 1.80 million tonnes grading 5.04% copper.

The Kakula southern decline and ore stockpiles containing a combined 1.33 million tonnes grading 4.65% copper (consisting of 602,000 high-grade tonnes @ 6.19% copper and 732,000 medium-grade tonnes @ 3.39% copper).

The Kansoko Mine and ore stockpiles containing a combined 521,000 tonnes grading 3.88% copper (consisting of 162,000 high-grade tonnes @ 5.82% copper and 359,000 medium-grade tonnes @ 3.00% copper).

Figure 1: Underground development completed at Kakula Mine to September 28, 2021 (in black).

Kakula is projected to be the world’s highest-grade major copper mine, with an initial mining rate of 3.8 Mtpa at an estimated, average feed grade of more than 6.0% copper over the first five years of operations, and 5.9% copper over the initial 10 years of operations. Phase 1 is expected to produce approximately 200,000 tonnes of copper per year, while the Phase 2 expansion is forecast to increase production to approximately 400,000 tonnes of copper annually. The project is on track to complete the Phase 2 expansion in Q3 2022. Based on independent benchmarking, the project’s phased expansion scenario to 19 Mtpa would position Kamoa-Kakula as the world’s second-largest copper mining complex, with peak annual copper production of more than 800,000 tonnes.

The Kamoa-Kakula Copper Project is a joint venture between Ivanhoe Mines (39.6%), Zijin Mining Group (39.6%), Crystal River Global Limited (0.8%) and the Government of the Democratic Republic of Congo (20%). A 2020 independent audit of Kamoa-Kakula’s greenhouse gas intensity metrics performed by Hatch Ltd. of Mississauga, Canada, confirmed that the project will be among the world’s lowest greenhouse gas emitters per unit of copper produced.

Study work advancing to accelerate Phase 3 mine and concentrator expansion

Study work for the Phase 3 mine and concentrator expansion is underway, which includes optimization work to determine mining production capacity and costs at the various mining areas on the Kamoa-Kakula complex, including expanded facilities at the Kansoko Mine, Kamoa North (including the Bonanza Zone) and Kakula West.

This work also will determine the optimal sizing of the Phase 3 concentrator, which was outlined as a further expansion of 3.8 Mtpa in the Kamoa-Kakula Integrated Development Plan announced in September 2020. In addition, the studies will take into consideration the expected timeline for the upgrade of turbine 5 at the Inga II hydropower complex to provide 162 megawatts of renewable hydropower, as well as the construction of a direct-to-blister smelter.

Once the optimization work is completed, Kamoa Copper will advance into a more detailed phase of design and engineering work with its objective to accelerate the Phase 3 concentrator expansion.

Pipe fitters Thara Ngoie (left) and Fanfan Kapepe installing pumps in the new pumping station at the Kansoko Mine.

(L-R) Kamoa Copper’s Pontien Kalala, JanStrydom and Mark Farren inspecting the first mined-out stope in the Kakula Mine being filled with paste backfill. Approximately 50% of the tailings are mixed with cement and pumped back underground to fill mined-out tunnels.

Mwadingusha hydropower plant fully operational and providing enough clean electricity for Kamoa-Kakula’s phases 1 and 2; Kamoa Copper’s green energy focus now shifting to the Inga II hydropower plant as the source of additional clean electricity for Kamoa-Kakula expansions

All six new turbines at the Mwadingusha hydropower plant now have been synchronized to the national electrical grid, with each generating unit producing approximately 13 megawatts (MW) of power, for a combined output of approximately 78 MW.

Kamoa-Kakula’s energy company has agreed to assist with the maintenance of the Mwadingusha turbines and a maintenance agreement between the state-owned power company SNEL and Ivanhoe Mines Energy is being drafted.

The Mwadingusha hydropower refurbishment project was awarded the ‘Best Public- Private Partnership Project of the Year’ at the recent 2021 DRC Energy Conference in Lubumbashi, organized by the Federation des Enterprise du Congo (the DRC Business Federation).

Ivanhoe Mines’ Louis Watum (left) and Bosco Kayombo, CEO of SNEL (right), receiving the award for the ‘Best Public-Private Partnership Project of the Year’ from Eve Bazaïba, Deputy DRC Prime Minister (centre).

In early August 2021, Kamoa-Kakula’s energy company signed an extension of the existing financing agreement with SNEL to upgrade turbine 5 at the Inga II hydropower complex. Since June 2021, rehabilitation scoping works and technical visits have been conducted by Stucky Ltd., of Renens, Switzerland, and Voith Hydro of Heidenheim, Germany, a leading engineering group. Voith, the contractor for the turbine 5 upgrade, has successfully rehabilitated two turbine generators at the adjoining Inga I hydropower plant, a project that was financed by the World Bank.

Early works related to the removal of sand from area around turbine 5 is in progress, which will allow the engineering team to complete the scoping work. Ivanhoe expects to soon be in a position to provide an update on the expected upgrading costs for turbine 5 as well as the expected timeline for completion of the upgrading project.

Turbine 5 is expected to produce 162 MW of renewable hydropower, providing the Kamoa-Kakula Copper Complex and the planned, associated smelter with abundant, sustainable electricity for future expansions.

Kamoa Copper partnership continues COVID-19 vaccination efforts for employees and residents who live in host communities

Kamoa-Kakula has successfully focused on prevention, preparation, and mitigation in managing the risks associated with COVID-19. Large-scale testing, combined with focused preventative measures, ensured that positive cases were quickly identified, isolated, and treated, with cross contamination kept to a minimum. Maintaining this high standard of risk management remains the main focus to prevent future cases.

With the support of the Democratic Republic of Congo government, UNICEF and other stakeholders, Kamoa Copper SA completed its first round of COVID-19 vaccinations in June 2021. In conjunction with the DRC government’s extended program of vaccinations, the second round of COVID-19 vaccinations at Kamoa-Kakula commenced in mid-August. The vaccine is available for all Kamoa Copper employees, contractors and residents living in the mine’s host communities.

The Kamoa COVID-19 hospital continues to treat patients when required, as construction progresses well for the expansion and upgrade of the primary healthcare wing. Kamoa-Kakula’s highly experienced medical team applies the latest medical treatments, supported by a world-leading emergency response and paramedic team.

As the pandemic evolves, the medical team at the Kamoa hospital continues to review and update risk mitigation protocols, while ensuring that new medical advances are investigated and applied to protect the health and safety of employees and community members.

A yellow-billed kite flying above the Kamoa-Kakula Mine. Kamoa Copperis focused on being responsible stewards of the environment, helping to protect the region’s flora, fauna and biodiversity.

Alice Mboy, Kamoa Copper’s Senior Community Relations Officer, presenting awards to students at the Muvunda primary school graduation ceremony. The new school in the village of Muvunda is a Kamoa Copper community initiative to increase education opportunities for families living near the Kamoa-Kakula Project.

Qualified Persons

Disclosures of a scientific or technical nature regarding development scenarios at the Kamoa-Kakula Project in this news release have been reviewed and approved by Steve Amos, who is considered, by virtue of his education, experience and professional association, a Qualified Person under the terms of NI 43-101. Mr. Amos is not considered independent under NI 43-101 as he is Kamoa Copper’s Head of Projects. Mr. Amos has verified the technical data disclosed in this news release.

Other disclosures of a scientific or technical nature regarding the stockpiles in this news release have been reviewed and approved by George Gilchrist, who is considered, by virtue of his education, experience and professional association, a Qualified Person under the terms of NI 43-101. Mr. Gilchrist is not considered independent under NI 43-101 as he is the Vice President, Resources of Ivanhoe Mines. Mr. Gilchrist has verified the other technical data related to the stockpiles disclosed in this news release.

The stockpile grade estimates contained in this release are based upon bulk ore sampling from material being fed to the plant from surface stockpiles, and underground vertical channel sample profiles from recent development. Channel sample profiles are cut approximately 15 metres apart in 1-metre vertical increments across the full vertical exposure using a handheld grinder, with a 100-to-150-gram sample collected. The samples are pulverized at the project’s onsite laboratory and analyzed using a portable XRF (pXRF) instrument. Kamoa Copper has routinely analyzed its exploration drill core for copper using pXRF, in addition to analysis at a commercial laboratory using four acid digest and ICP-OES. This data has demonstrated that pXRF results can be relied upon for grade control and run-of-mine sampling. Due to rounding, numbers presented throughout this news release may not add up precisely.

Ivanhoe has prepared an independent, NI 43-101-compliant technical report for the Kamoa-Kakula Project, which is available on the company’s website and under the company’s SEDAR profile at www.sedar.com:

- Kamoa-Kakula Integrated Development Plan 2020 dated October 13, 2020, prepared by OreWin Pty Ltd., China Nerin Engineering Co., Ltd., DRA Global, Epoch Resources, Golder Associates Africa, KGHM Cuprum R&D Centre Ltd., Outotec Oyj, Paterson and Cooke, Stantec Consulting International LLC, SRK Consulting Inc., and Wood plc.

The technical report includes relevant information regarding the assumptions, parameters and methods of the mineral resource estimates on the Kamoa-Kakula Project cited in this news release, as well as information regarding data verification, exploration procedures and other matters relevant to the scientific and technical disclosure contained in this news release.

About Ivanhoe Mines

Ivanhoe Mines is a Canadian mining company focused on advancing its three principal joint-venture projects in Southern Africa: the development of major new, mechanized, underground mines at the Kamoa-Kakula copper discoveries in the Democratic Republic of Congo and at the Platreef palladium-rhodium-platinum-nickel-copper-gold discovery in South Africa; and the extensive redevelopment and upgrading of the historic Kipushi zinc-copper-germanium-silver mine, also in the Democratic Republic of Congo.

Kamoa-Kakula began producing copper concentrates in May 2021 and, through phased expansions, is positioned to become one of the world’s largest copper producers. Kamoa-Kakula and Kipushi are being powered by clean, renewable hydro-generated electricity and are projected to be among the world’s lowest greenhouse gas emitters per unit of metal produced. Ivanhoe Mines has pledged to achieve net-zero operational greenhouse gas emissions (Scope 1 and 2) at the Kamoa-Kakula Copper Mine when large-scale electric, hydrogen and hybrid underground mining equipment become commercially available. Ivanhoe also is exploring for new copper discoveries on its Western Foreland exploration licences in the Democratic Republic of Congo, near the Kamoa-Kakula Project.

Information contacts

Investors: Bill Trenaman +1.604.331.9834 / Media: Matthew Keevil +1.604.558.1034

Forward-looking statements

Certain statements in this release constitute “forward-looking statements” or “forward-looking information” within the meaning of applicable securities laws. Such statements and information involve known and unknown risks, uncertainties and other factors that may cause the actual results, performance or achievements of the company, its projects, or industry results, to be materially different from any future results, performance or achievements expressed or implied by such forward-looking statements or information. Such statements can be identified by the use of words such as “may”, “would”, “could”, “will”, “intend”, “expect”, “believe”, “plan”, “anticipate”, “estimate”, “scheduled”, “forecast”, “predict” and other similar terminology, or state that certain actions, events or results “may”, “could”, “would”, “might” or “will” be taken, occur or be achieved. These statements reflect the company’s current expectations regarding future events, performance and results and speak only as of the date of this release.

Such statements include without limitation, the timing and results of: (i) statements regarding Ivanhoe’s guidance for contained copper in concentrate expected to be produced by Kamoa-Kakula for 2021 has been tightened to 85,000 to 95,000 tonnes; (ii) statements regarding the expectation that Phase 2 of the project’s development when the Kakula concentrator processing capacity doubles to 7.6 Mtpa is to be commissioned in Q3 2022; (iii) statements regarding Kakula is projected to be the world’s highest-grade major copper mine, with an initial mining rate of 3.8 Mtpa at an estimated, average feed grade of more than 6.0% copper over the first five years of operations and 5.9% copper over the initial 10 years of operations; (iv) statements regarding Kamoa-Kakula’s Phase 1 is expected to produce approximately 200,000 tonnes of copper per year, and Phases 1 and 2 combined are forecast to produce approximately 400,000 tonnes of copper per year; (v) statements regarding based on independent benchmarking, the project’s phased expansion scenario to 19 Mtpa would position Kamoa-Kakula as the world’s second largest copper mining complex, with peak annual copper production of more than 800,000 tonnes; (vi) statements regarding Kamoa-Kakula will be among the world’s lowest greenhouse gas emitters per unit of copper produced; (vii) statements regarding the adjustments being incorporated into the Phase 1 processing circuit should position Kamoa-Kakula to achieve 2021 copper production in the upper end of the previous guidance of 80,000 to 95,000 tonnes; (viii) statements regarding approximately one half of the mine’s tailings will be sent back underground; and (ix) statements regarding an upgraded turbine 5 at Inga II is expected to produce 162 megawatts of renewable hydropower, providing the Kamoa-Kakula Copper Complex and associated smelter with abundant sustainable electricity for future expansions.

As well, all of the results of the Kakula definitive feasibility study, the Kakula-Kansoko pre-feasibility study and the Kamoa-Kakula preliminary economic assessment, constitute forward-looking statements or information, and include future estimates of internal rates of return, net present value, future production, estimates of cash cost, proposed mining plans and methods, mine life estimates, cash flow forecasts, metal recoveries, estimates of capital and operating costs and the size and timing of phased development of the projects. Furthermore, with respect to this specific forward-looking information concerning the development of the Kamoa-Kakula Project, the company has based its assumptions and analysis on certain factors that are inherently uncertain. Uncertainties include: (i) the adequacy of infrastructure; (ii) geological characteristics; (iii) metallurgical characteristics of the mineralization; (iv) the ability to develop adequate processing capacity; (v) the price of copper; (vi) the availability of equipment and facilities necessary to complete development; (vii) the cost of consumables and mining and processing equipment; (viii) unforeseen technological and engineering problems; (ix) accidents or acts of sabotage or terrorism; (x) currency fluctuations; (xi) changes in regulations; (xii) the compliance by joint venture partners with terms of agreements; (xiii) the availability and productivity of skilled labour; (xiv) the regulation of the mining industry by various governmental agencies; (xv) the ability to raise sufficient capital to develop such projects; (xvi) changes in project scope or design; and (xvii) political factors.

Forward-looking statements and information involve significant risks and uncertainties, should not be read as guarantees of future performance or results and will not necessarily be accurate indicators of whether or not such results will be achieved. A number of factors could cause actual results to differ materially from the results discussed in the forward-looking statements or information, including, but not limited to, the factors discussed below and under “Risk Factors”, and elsewhere in this release, as well as unexpected changes in laws, rules or regulations, or their enforcement by applicable authorities; the failure of parties to contracts with the company to perform as agreed; social or labour unrest; changes in commodity prices; and the failure of exploration programs or studies to deliver anticipated results or results that would justify and support continued exploration, studies, development or operations.

Although the forward-looking statements contained in this release are based upon what management of the company believes are reasonable assumptions, the company cannot assure investors that actual results will be consistent with these forward-looking statements. These forward-looking statements are made as of the date of this release and are expressly qualified in their entirety by this cautionary statement. Subject to applicable securities laws, the company does not assume any obligation to update or revise the forward-looking statements contained herein to reflect events or circumstances occurring after the date of this release.

The company’s actual results could differ materially from those anticipated in these forward-looking statements as a result of the factors set forth below in the “Risk Factors” section in the company’s 2021 Q2 MD&A and its current annual information form.

English

English Français

Français 日本語

日本語 中文

中文