Pre-production ore stockpiles now hold 1.25 million tonnes grading 3.75% copper, containing more than 46,700 tonnes of copper

Underground development totalling 2,163 metres completed in November; more than 26.8 kilometres now complete – 9.0 kilometres ahead of plan

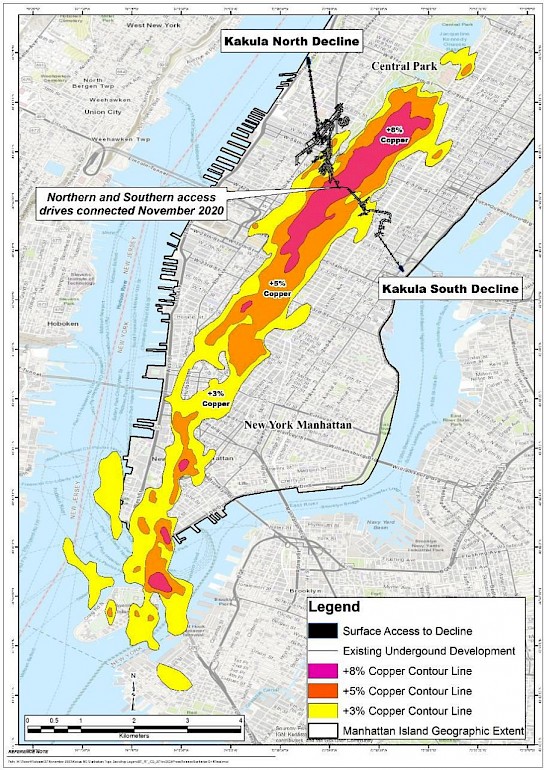

Access to Kakula’s +8% copper ore in the centre of deposit established with the connection of northern and southern main access tunnels in early November

In November, Kakula’s central connection development produced 93,000 tonnes grading 4.95% copper from the southern decline, including 41,000 tonnes of high-grade ore grading 7.82% copper, and 124,000 tonnes grading 5.03% copper from the northern decline

Overall progress of Kamoa-Kakula’s first phase, 3.8 Mtpa mining and milling operation now approximately 63% complete, with first copper concentrate production scheduled for July 2021

KOLWEZI, DEMOCRATIC REPUBLIC OF CONGO – Ivanhoe Mines (TSX: IVN; OTCQX: IVPAF) Co-Chairs Robert Friedland and Yufeng “Miles” Sun are pleased to announce that underground development at the Kamoa-Kakula Copper Project in the Democratic Republic of Congo (DRC) produced a combined 250,000 tonnes of ore grading 4.85% copper in November from the Kakula and Kansoko mines. The tonnage was 29% higher than achieved in October, while the monthly copper grade increased from 4.01% to 4.85%.

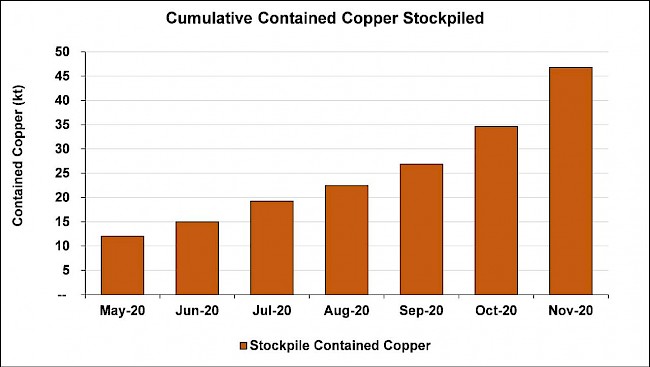

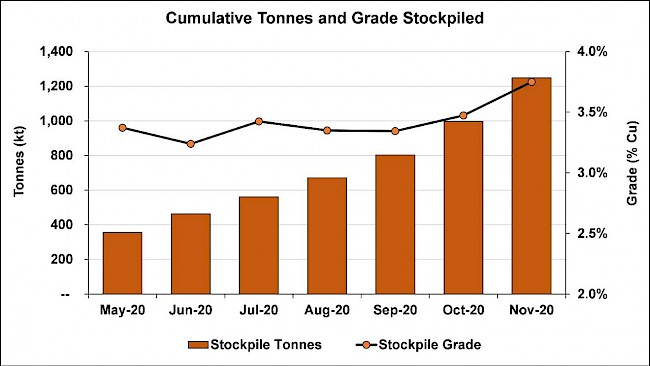

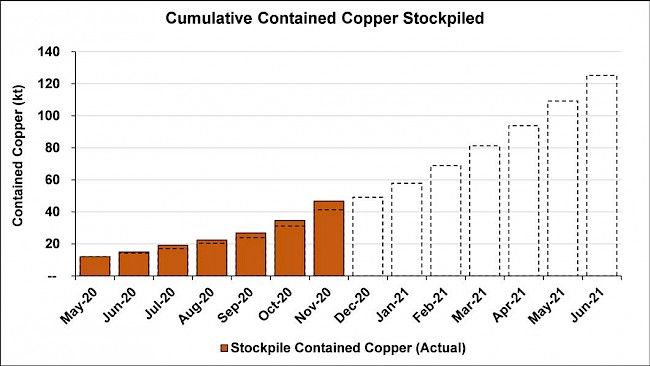

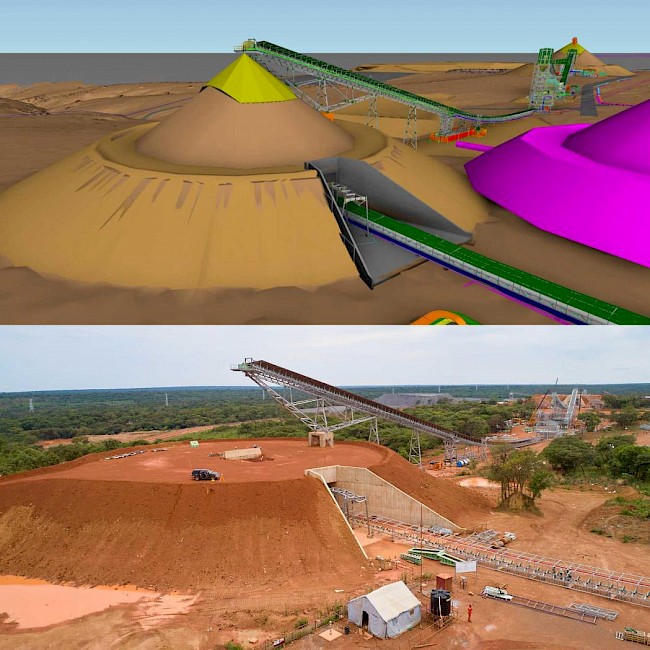

The project’s pre-production surface stockpiles now contain approximately 1.25 million tonnes of high-grade and medium-grade ore at an estimated grade of 3.75% copper. Contained copper in the stockpiles increased by approximately 12,100 tonnes in November – a 55% increase over October’s production – to a cumulative total of more than 46,700 tonnes (the current copper price is approximately US$7,670 a tonne). The project is on track to have approximately three million tonnes of high-grade and medium-grade ore stockpiled on surface, containing more than 125,000 tonnes of copper, prior to the planned start of production in July 2021.

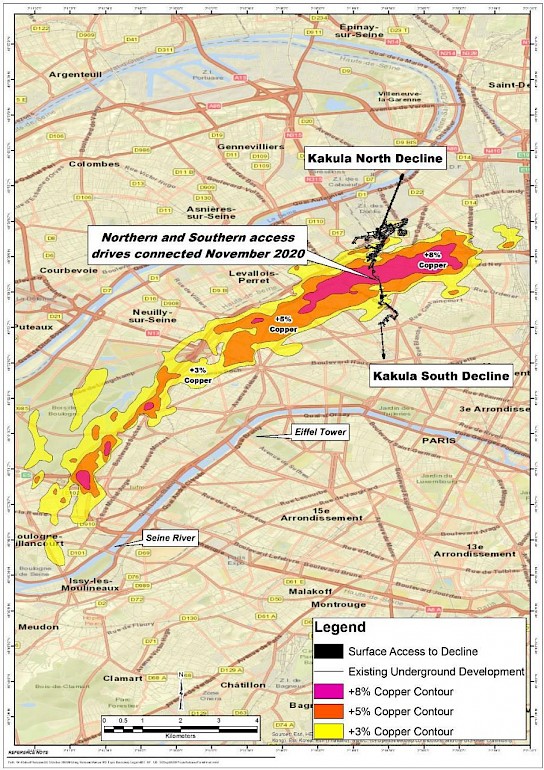

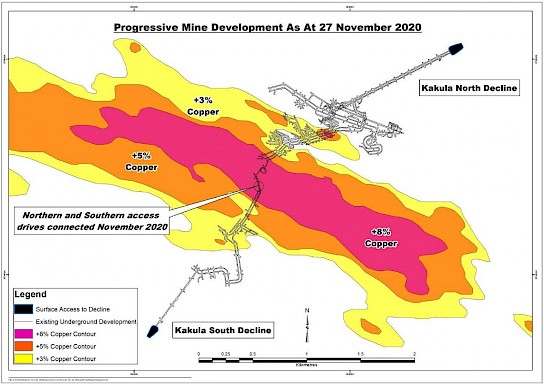

Mr. Friedland and Mr. Sun also noted that underground mine development totalled 2,163 metres in November – only 10 metres shy of establishing another new monthly record. A key milestone was achieved in early November with the joining of Kakula’s main northern and southern access tunnels, establishing access to begin mining Kakula’s high-grade ore in the centre of the orebody grading approximately +8% copper (see figures 1, 2 and 3). The holing event was advanced only from one end for the last few days as a standard safety precaution, which had a minor effect on the metres achieved.

The holing has allowed Kakula’s mining crews to enlarge the development drifts in the centre of the deposit to 7-metres wide by 7-metres high (approximately 23-feet wide by 23-feet high) to take advantage of the excellent copper grades across a thick ore zone – providing a substantial increase in tonnes per metre of development.

November’s development brings total underground development to more than 26.8 kilometres – approximately 9.0 kilometres ahead of schedule. The monthly total of 2,163 metres of underground development in November was comprised of 1,840 metres at the Kakula Mine and 323 metres at the Kansoko Mine, which is located at the Kamoa Deposit – approximately 10 kilometres north of the Kakula Mine.

Mark Farren, Kamoa Copper’s CEO, commented: “November was a great month for mine development. Not only did we join the Kakula’s main access tunnels that now provides a transportation and ventilation connection between the northern and southern declines – a distance of approximately four kilometres, we also achieved record ore production at significantly better copper grades. We expect this production trend to continue as additional mining crews begin working in the centre of the high-grade Kakula orebody. We also saw a sharp increase in copper grades at the Kansoko Mine in November, resulting from ongoing exposure of a rapidly thickening layer of copper-rich siltstone.”

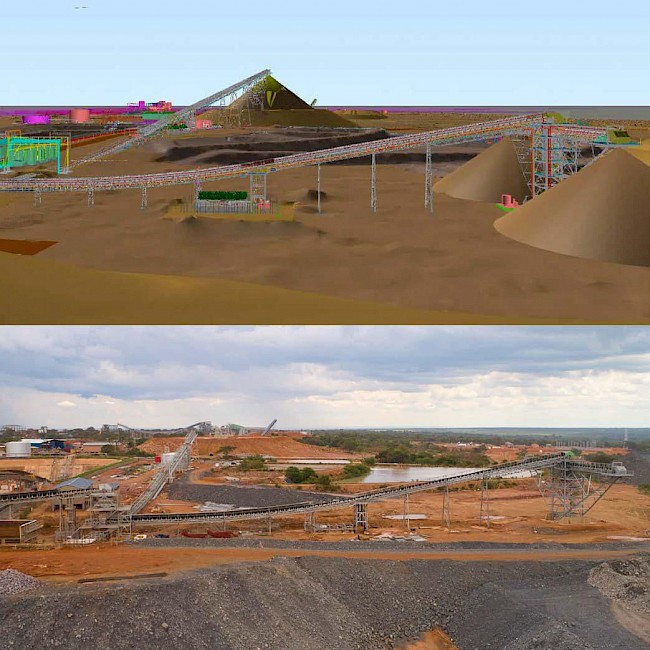

“This month we expect to achieve three key construction milestones – energizing the newly installed 220-kilovolt power line feeding Kamoa-Kakula with hydro-generated electricity from the national grid; synchronization of the first of six turbines at the refurbished Mwadingusha hydropower plant onto the national grid; and commissioning the main surface rock-handling, by-pass conveyor system that will enable the delivery of ore from the Kakula Mine directly to the concentrator plant stockpiles,” Mr. Farren added.

Underground mining crews at Kakula are focused on developing the high grade, drift-and-fill mining blocks in the centre of the orebody. Opening up of the mining footprint for these high grade, drift-and-fill mining areas entails, by necessity, development work in areas of low-, medium- and high-grade ore, and is designed to coincide with the start-up of the processing plant next year. This will allow crews to deliver significant tonnage of high-grade ore directly from Kakula’s underground workings to the processing plant.

While most of the underground development at the Kansoko Mine is in medium-grade ore, in late November mining crews entered the deposit’s initial high-grade ore zone, with 2,100 tonnes of high-grade ore grading 6.66% copper mined by month’s end. Kansoko’s combined medium-grade and high-grade ore mined in November was approximately 33,000 tonnes at an average grade of 3.87% copper. Ongoing exposure of a rapidly thickening siltstone is the reason for a sharp increase in copper grades at Kansoko in November. Siltstone is a rock type with a strong influence on copper mineralization at Kamoa-Kakula.

Kansoko is being developed by training crews and will be a supplemental source of ore for Phase 2 of the project’s development when the Kakula concentrator processing capacity doubles to 7.6 million tonnes per annum (Mtpa) − currently planned to be commissioned in Q3 2022.

Phase 1 copper production from the Kakula Mine is scheduled to begin in July 2021. Kakula is projected to be the world’s highest-grade major copper mine, with an initial mining rate of 3.8 Mtpa at an estimated average feed grade of more than 6.0% copper over the first five years of operation. Phases 1 and 2 combined are forecast to produce approximately 400,000 tonnes of copper per year. Based on independent benchmarking, the project’s phased expansion scenario to 19 Mtpa would position Kamoa-Kakula as the world’s second largest copper mining complex, with peak annual copper production of more than 800,000 tonnes.

An independent audit of Kamoa-Kakula’s greenhouse gas intensity metrics performed by Hatch Ltd., of Mississauga, Canada, confirmed that the project will be among the world’s lowest greenhouse gas emitters per unit of copper produced.

Watch a short, fly-over video showcasing the ongoing construction of the Kakula Mine and Phase 1, 3.8 Mtpa concentrator plant: https://vimeo.com/485580022/276d6411df

Left to right:Magloire Kashiba, Production Manager; Jan Strydom, Managerial Leader: Operations; Marna Cloete, Ivanhoe Mines President and CFO; and Pontien Kalala – Section Manager, celebrate the joining of Kakula’s main access tunnels in early November that now provides a transportation and ventilation connection between the northern and southern declines.

In November, the Kamoa-Kakula’s surface construction team achieved five million hours worked without incurring a lost time accident.

Drilling the face of a 7-metre-wide by 7-metre-high development drift in the high-grade centre of the Kakula Deposit.

November’s ore production 29% higher than October, with monthly copper grade increasing from 4.01% to 4.85%; pre-production surface ore stockpiles now total approximately 1.25 million tonnes grading 3.75% copper

In November, mining crews at the Kakula and Kansoko mines mined and transported to surface approximately 250,000 tonnes of ore grading 4.85% copper. This brings the project’s total pre-production high- and medium-grade ore stockpiles to approximately 1.25 million tonnes at an estimated grade of 3.75% copper. An additional 622,000 tonnes of low-grade development ore also has been stockpiled on surface.

November’s ore production is approximately 29% higher than the 194,000 tonnes grading 3.47% copper mined in October, and approximately 89% higher than the 132,000 tonnes grading 3.31% mined in September. The project is well positioned for continued acceleration in the tonnage, as well as an increase in the grade, of ore added to the surface stockpiles as more mining crews commence mining in the higher-grade areas of the Kakula and Kansoko mines.

Chart 1: Cumulative tonnes and grade of pre-production ore stockpiles at the Kakula and Kansoko mines from May 2020 to November 2020.

Chart 2: Growth in contained copper in pre-production ore stockpiles at the Kakula and Kansoko mines from May 2020 to November 2020.

Chart 3: Projected growth in contained copper in the pre-production stockpiles at the Kakula and Kansoko mines up to the planned start of Phase 1 production in July 2021. Dotted line are projections based on the 2020 pre-feasibility study.

The ore being mined from the northern portion of the Kakula Mine is transported to surface via the conveyor system and placed on a blended surface stockpile that now contains approximately 763,000 tonnes grading an estimated 3.93% copper.

Additional, pre-production ore stockpiles are located at the Kakula southern decline (approximately 107,000 tonnes of high-grade ore grading 6.11% copper and 224,000 tonnes of medium-grade ore grading 2.64% copper) and the Kansoko decline (approximately 2,100 tonnes of high-grade ore grading 6.66% copper and 151,000 tonnes of medium-grade ore grading 2.82% copper).

Kakula’s main pre-production stockpiles at the northern declines. The blended stockpiles currently contain approximately 763,000 tonnes grading 3.93% copper.

Kakula southern decline ore stockpiles containing approximately 107,000 tonnes of high-grade ore grading 6.11% copper, and 224,000 tonnes of medium-grade ore grading 2.64% copper.

Kansoko decline ore stockpiles containing 153,000 tonnes grading 2.82% copper, including the initial 2,100 tonnes of high-grade ore grading 6.66% copper.

Figure 1: The overall 13.3-kilometre-long Kakula Deposit overlain on southern Manhattan Island to provide a sense of the scale of the deposit.

Figure 2: The overall 13.3-kilometre-long Kakula Deposit overlain on Paris to provide a sense of the scale of the deposit and underground operations.

Figure 3: Underground development completed at Kakula Mine to November 27, 2020 (in black).

Construction of the initial 3.8-Mtpa concentrator plant and other surface infrastructure rapidly progressing; earthworks and civil works started, and EPCM contract awarded for the second 3.8-Mtpa concentrator plant

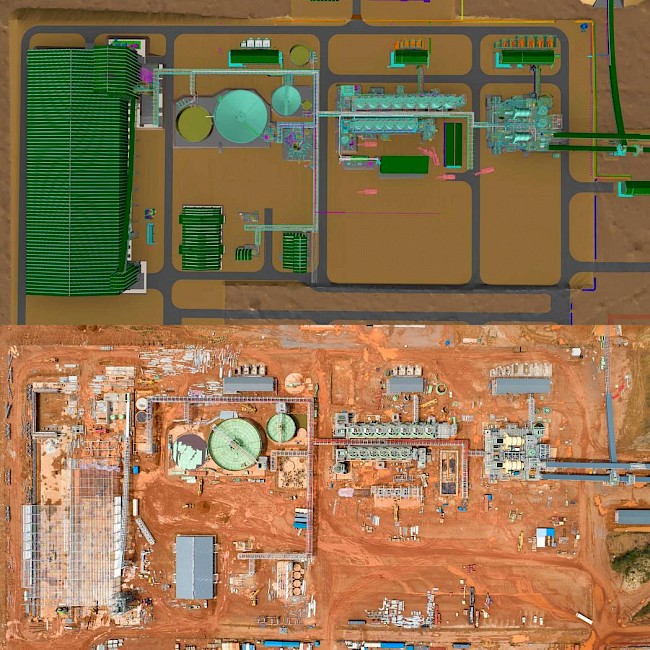

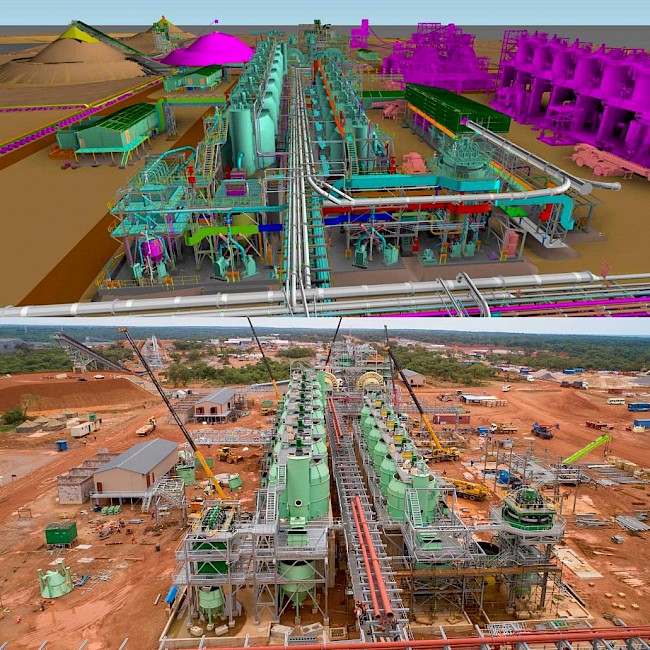

Overall progress of Kamoa-Kakula’s first-phase, 3.8 Mtpa mining and milling operation (covering mine infrastructure, concentrator plant and surface infrastructure) now is approximately 63% complete, up from 58% last month. Overall construction of the project’s first-phase 3.8 Mtpa concentrator plant and associated facilities is advancing rapidly and is approximately 35% complete, up from 28% last month. The concentrator plant is expected to be mechanically complete in Q2 2021, with first copper concentrate production scheduled for July 2021.

Civil works for the initial concentrator plant are more than 90% complete, with approximately 28,000 cubic metres of concrete poured to date. All major construction areas have handed over to the steel, mechanical, piping and platework (SMPP) contractor.

More than 2,000 truckloads of equipment have been delivered to site, including the final major pieces of equipment − two 80-MVA/220-kilovolt (kV) electrical transformers. The transformers have been placed into position at the main Kakula substation and construction of the project’s various electrical substations is progressing well.

All structural steel has been delivered to site, as well as the bulk of the platework and piping. Piping installation has started, as has electrical installation of cable racks and cable installation.

Over 3,000 tonnes of steel (of a total of 5,700 tonnes) has been installed. SMPP erection and installation has commenced in all areas of the concentrator plant and is well advanced. Electrical installation is underway in the milling, flotation and thickener areas.

A recent focus area was to install roof sheeting on the reagent storage building and the concentrate storage building to allow on-site fabrication work to continue during periods of rain.

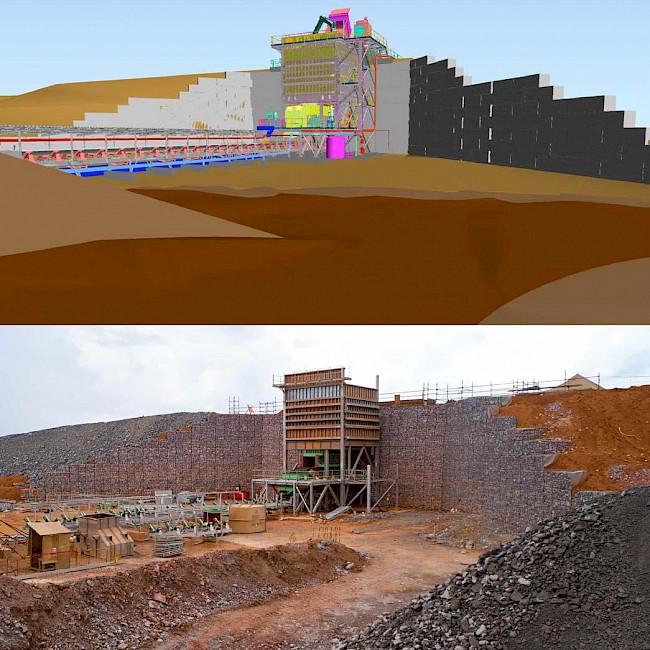

Steel erection for Kakula’s first phase, backfill paste plant is well advanced with the bulk of the outer structure complete including the installation of the gantry crane, the installation of the two 2000t cement silos is underway. Structural steel erection is scheduled to be completed in early 2021.

The backfill plant will be used to mix tailings from the processing plant with cement to produce paste backfill. The backfill will be pumped back into the mine and used to help support mined-out areas. Approximately one half of the mine’s tailings will be sent back underground, significantly reducing the surface tailings storage.

Construction of the tailings dam is progressing well and is scheduled to be completed well ahead of the required date. Installation of the three tailings lines and the tailings return water line is nearing completion.

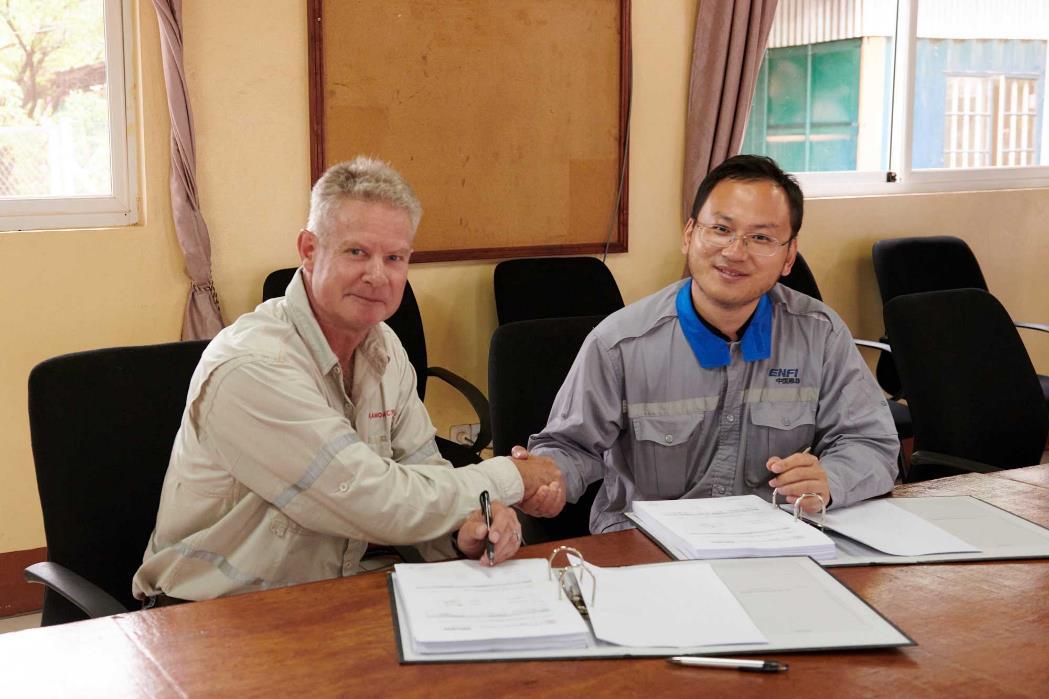

The long-lead items for the second 3.8-Mtpa concentrator plant have been ordered and the Phase 2 of the project’s development is underway. Contracts have placed for the earthworks, and civil works and bush clearing has started. The Engineering, Procurement and Construction Management (EPCM) contract also has been signed with ENFI Engineering Corporation, of Beijing, China.

Mark Farren, Kamoa Copper’s CEO (left), and Huang Yingsheng, ENFI’s Director of International Business (right), sign the ECPM contract for Kamoa-Kakula’s Phase 2 concentrator.

A 3D, overhead illustration of the finished the Phase 1, 3.8 Mtpa concentrator plant. The picture immediately below shows the current construction progress (approximately 41% complete).

A 3D illustration of the finished ball mills area for the Phase 1, 3.8 Mtpa concentrator, with the next two ball mills for the recently-initiated Phase 2 concentrator plant shown in magenta. The picture immediately below shows the current construction progress (approximately 59% complete).

A 3D illustration of Kakula’s initial 3.8 Mtpa concentrator plant, with the recently-initiated Phase 2 3.8-Mtpa processing plant shown in magenta. The picture immediately below shows the currentconstruction progress (approximately 48% complete).

A 3D illustration of the initial high-pressure-grinding-rolls (HPGR) stockpile, with the recently-initiated second HPGR stockpile shown in magenta. The picture immediately below shows the currentconstruction progress (approximately 70% complete).

A 3D illustration of the tailings thickener (larger one in green) and concentrate thickener (smaller one in green), with the concentrate bagging plant shown in the background and the Phase 2 thickeners shown in magenta. The picture immediately below shows the currentconstruction progress (approximately 73% complete).

A 3D illustration of the reagent storage building, area, bagging plant and concentrate storage building, with Phase 2 shown in magenta. The picture immediately below shows the currentconstruction progress (approximately 30% complete).

Construction of the regrind mills at the concentrator plant is progressing rapidly.

Workers putting the finishing touches to the screening plant and surface ore conveyor system.

Ongoing construction of the concentrate bagging plant.

Workers installing a section for the two, 2,000-tonne silos at the backfill plant.

Watch a short, time-lapse video of the construction of the backfill plant’s 2,000-tonne silos:https://vimeo.com/485583080/a80283b88f

A 3D illustration of Kakula’s first phase, finished backfill plant, with the current construction (approximately 40% complete) and the initial 3.8 Mtpa concentrator plant in the background shown immediately below. The backfill plant will blend tailings from the concentrator with cement to produce paste backfill that will pumped back into the mine and used to help support mined-out areas. Approximately one half of the mine’s tailings will be sent back underground.

Watch a short, fly-over video of the construction of the backfill plant: https://vimeo.com/485579247/bc8297d722

A 3D illustration of Kakula’s bulk reclaim tip system that will be used to feed ore from Kakula’s surface stockpiles (and ore from the Kansoko Mine when Phase 2 operations begin) to the processing circuit. The current construction isshown immediately below (approximately 54% complete).

A 3D illustration of Kakula’sby-pass stockpile feed conveyor system. The current construction isshown immediately below (approximately 62% complete).

Electrician Abel Muianga installing a high-voltage electrical control box at the backfill plant.

Advanced, detailed discussions underway for the marketing of Kakula’s copper concentrates

Kamoa-Kakula is in advanced, detailed discussions with a number of parties with respect to the sale of its copper concentrates. Kakula is expected to produce an extremely high grade and clean copper concentrate (containing over 55% copper) that will be highly coveted by copper smelters around the world. Metallurgical test work indicates that the Kakula concentrates contain extremely low arsenic levels by world standards – approximately 0.01%.

Kamoa-Kakula preparing to be connected to the national power grid, providing clean, renewable 220-kV hydropower; first of six turbines at the refurbished Mwadingusha hydropower plant to be synchronized onto the national grid in December

Later this month, Kamoa-Kakula is expected to tie in the 35-kilometre, 220-kilovolt (kV) power line connecting theWestern Dispatch substation in Kolwezi to Kamoa-Kakula, and supply the project with reliable and clean hydro-generated electricity from the national grid.

Watch a short, fly-over video of the construction of the Kakula main electrical substation: https://vimeo.com/485582554/2b5d9b4741

Ivanhoe Mines Energy DRC is pleased to announce that the first of three turbines to be fully assembled this year at Mwadingusha hydropower plant went into final commissioning tests on November 26. The synchronization of this turbine onto the national electrical grid is scheduled for December 10, paving the way for the commissioning, in sequence, of the plant’s remaining five generating units, ensuring that Kamoa-Kakula’s power requirements of are met ahead of the commissioning of the concentrator plant. The fully-refurbished hydropower plant is expected to deliver approximately 72 megawatts of power to the national grid.

New water-pressure relief valves installed at the Mwadingusha hydropower plant.

In November, Mwadingusha’s water intake channel was filled in preparation for the commissioning and synchronization of the first of six refurbished turbines onto the national electrical grid.

Kamoa-Kakula’s COVID-19 prevention initiatives focused on risk mitigation

Kamoa-Kakula’s prevention measures remain strictly enforced. Rigorous testing, physical distancing, wearing face masks, frequent hand washing and contact-tracing measures are still in place to protect the safety and health of the workforce and community members.

The project has established a COVID-19 isolation facility at the Kamoa camp. Potential symptomatic patients are moved to this facility, where they will be isolated, tested and treated. Once patients have recovered and are deemed no longer infectious, they can return to work only after an additional quarantine period determined by the project’s medical staff.

As the pandemic evolves, the medical team at Kamoa-Kakula continues to review and update its risk mitigation protocols. The project’s preventative measures are at the highest international standards and should there be a case internally, the risk of spreading or cross-contamination is considered to be very low.

The Kamoa-Kakula Copper Project is a joint venture between Ivanhoe Mines (39.6%), Zijin Mining Group (39.6%), Crystal River Global Limited (0.8%) and the DRC government (20%).

Electrician Simon Ndjamba Merve at Kakula’s new underground water-pumping station.

Olivier Kongo, one of the more than 6,300 employees and contractors building Kamoa-Kakula into the world’s next great copper mine.

Lunchtime at one of Kamoa-Kakula’s new dining facilities.

About Ivanhoe Mines

Ivanhoe Mines is a Canadian mining company focused on advancing its three principal joint-venture projects in Southern Africa: the development of major new, mechanized, underground mines at the Kamoa-Kakula copper discoveries in the DRC and at the Platreef palladium-platinum-nickel-copper-rhodium-gold discovery in South Africa; and the extensive redevelopment and upgrading of the historic Kipushi zinc-copper-germanium-silver mine, also in the DRC. Kamoa-Kakula is expected to begin producing copper in July 2021 and, through phased expansions, is positioned to become one of the world’s largest copper producers. Kamoa-Kakula and Kipushi will be powered by clean, renewable hydro-generated electricity and will be among the world’s lowest greenhouse gas emitters per unit of metal produced. Ivanhoe also is exploring for new copper discoveries on its wholly-owned Western Foreland exploration licences in the DRC, near the Kamoa-Kakula Project.

Qualified Persons

Disclosures of a scientific or technical nature regarding development scenarios at the Kamoa-Kakula Project in this news release have been reviewed and approved by Steve Amos, who is considered, by virtue of his education, experience and professional association, a Qualified Person under the terms of NI 43-101. Mr. Amos is not considered independent under NI 43-101 as he is the Head of the Kamoa Project. Mr. Amos has verified the technical data disclosed in this news release.

Other disclosures of a scientific or technical nature regarding the stockpiles in this news release have been reviewed and approved by George Gilchrist, who is considered, by virtue of his education, experience and professional association, a Qualified Person under the terms of NI 43-101. Mr. Gilchrist is not considered independent under NI 43-101 as he is the Vice President, Resources of Ivanhoe Mines. Mr. Gilchrist has verified the other technical data disclosed in this news release.

The stockpile grade estimates contained in this release are based upon bulk ore sampling from earlier underground headings, and vertical channel sample profiles from recent development. Bulk ore sampling was done on each heading every second blast and three 5-kilogram samples were taken. Since the beginning of October 2020, channel sample profiles are the primary data informing the stockpile grade estimates. These are cut approximately 15 metres apart in 1-metre vertical increments across the full vertical exposure using a handheld grinder, with a 100-to-150-gram sample collected. The samples are pulverized at the project’s onsite laboratory and analyzed using a portable XRF (pXRF) instrument. Kamoa Copper has routinely analyzed its exploration drill core for copper using pXRF, in addition to analysis at a commercial laboratory using four acid digest and ICP-OES. This data has demonstrated that pXRF results can be relied upon for grade control and run-of-mine sampling.

Ivanhoe has prepared an independent, NI 43-101-compliant technical report for the Kamoa-Kakula Project, which is available on the company’s website and under the company’s SEDAR profile at www.sedar.com:

- Kamoa-Kakula Integrated Development Plan 2020 dated October 13, 2020, prepared by OreWin Pty Ltd., China Nerin Engineering Co., Ltd., DRA Global, Epoch Resources, Golder Associates Africa, KGHM Cuprum R&D Centre Ltd., Outotec Oyj, Paterson and Cooke, Stantec Consulting International LLC, SRK Consulting Inc., and Wood plc.

The technical report includes relevant information regarding the assumptions, parameters and methods of the mineral resource estimates on the Kamoa-Kakula Project cited in this news release, as well as information regarding data verification, exploration procedures and other matters relevant to the scientific and technical disclosure contained in this news release.

Information contacts

Investors: Bill Trenaman +1.604.331.9834 / Media: Matthew Keevil +1.604.558.1034

Forward-looking statements

Certain statements in this release constitute “forward-looking statements” or “forward-looking information” within the meaning of applicable securities laws. Such statements and information involve known and unknown risks, uncertainties and other factors that may cause the actual results, performance or achievements of the company, its projects, or industry results, to be materially different from any future results, performance or achievements expressed or implied by such forward-looking statements or information. Such statements can be identified by the use of words such as “may”, “would”, “could”, “will”, “intend”, “expect”, “believe”, “plan”, “anticipate”, “estimate”, “scheduled”, “forecast”, “predict” and other similar terminology, or state that certain actions, events or results “may”, “could”, “would”, “might” or “will” be taken, occur or be achieved. These statements reflect the company’s current expectations regarding future events, performance and results and speak only as of the date of this release.

Such statements include without limitation, the timing and results of: (i) statements regarding the Kamoa-Kakula Project is on track to have approximately three million tonnes of high-grade and medium-grade ore stockpiled on surface, containing more than 125,000 tonnes of copper, prior to the planned start of production in July 2021; (ii) statements regarding the expectation that the increased production of higher-grade ore to continue as additional mining crews begin working in the centre of the high-grade Kakula orebody; (iii) statements regarding the expectation that the project will achieve three key construction milestones in December – energizing the newly installed 220-kilovolt power line feeding Kamoa-Kakula with hydro-generated electricity from the national grid; synchronization of the first of six turbines at the refurbished Mwadingusha hydropower plant onto the national grid; and commissioning the main surface rock-handling, by-pass conveyor system that will enable the delivery of ore from the Kakula Mine directly to the concentrator plant stockpiles; (iv) statements regarding the expectation that Phase 2 of the project’s development when the Kakula concentrator processing capacity doubles to 7.6 Mtpa is to be commissioned in Q3 2022; (v) statements regarding Kakula is projected to be the world’s highest-grade major copper mine, with an initial mining rate of 3.8 Mtpa at an estimated average feed grade of more than 6.0% copper over the first five years of operation; (vi) statements regarding Phases 1 and 2 combined are forecast to produce approximately 400,000 tonnes of copper per year; statements regarding based on independent benchmarking, the project’s phased expansion scenario to 19 Mtpa would position Kamoa-Kakula as the world’s second largest copper mining complex, with peak annual copper production of more than 800,000 tonnes; (vii) statements regarding Kamoa-Kakula will be among the world’s lowest greenhouse gas emitters per unit of copper produced; (viii) statements regarding approximately one half of the mine’s tailings will be sent back underground; (ix) statements regarding Kakula is expected to produce an extremely high grade and clean copper concentrate (containing over 55% copper and extremely low arsenic levels by world standards – approximately 0.01%) that will be highly coveted by copper smelters around the world; and, (x) statements regarding the fully-refurbished Mwadingusha hydropower plant is expected to deliver approximately 72 megawatts of power to the national grid.

As well, all of the results of the Kakula definitive feasibility study, the Kakula-Kansoko pre-feasibility study and the Kamoa-Kakula preliminary economic assessment, constitute forward-looking statements or information, and include future estimates of internal rates of return, net present value, future production, estimates of cash cost, proposed mining plans and methods, mine life estimates, cash flow forecasts, metal recoveries, estimates of capital and operating costs and the size and timing of phased development of the projects. Furthermore, with respect to this specific forward-looking information concerning the development of the Kamoa-Kakula Project, the company has based its assumptions and analysis on certain factors that are inherently uncertain. Uncertainties include: (i) the adequacy of infrastructure; (ii) geological characteristics; (iii) metallurgical characteristics of the mineralization; (iv) the ability to develop adequate processing capacity; (v) the price of copper; (vi) the availability of equipment and facilities necessary to complete development; (vii) the cost of consumables and mining and processing equipment; (viii) unforeseen technological and engineering problems; (ix) accidents or acts of sabotage or terrorism; (x) currency fluctuations; (xi) changes in regulations; (xii) the compliance by joint venture partners with terms of agreements; (xiii) the availability and productivity of skilled labour; (xiv) the regulation of the mining industry by various governmental agencies; (xv) the ability to raise sufficient capital to develop such projects; (xiv) changes in project scope or design; and (xv) political factors.

Forward-looking statements and information involve significant risks and uncertainties, should not be read as guarantees of future performance or results and will not necessarily be accurate indicators of whether or not such results will be achieved. A number of factors could cause actual results to differ materially from the results discussed in the forward-looking statements or information, including, but not limited to, the factors discussed below and under “Risk Factors”, and elsewhere in this release, as well as unexpected changes in laws, rules or regulations, or their enforcement by applicable authorities; the failure of parties to contracts with the company to perform as agreed; social or labour unrest; changes in commodity prices; and the failure of exploration programs or studies to deliver anticipated results or results that would justify and support continued exploration, studies, development or operations.

lthough the forward-looking statements contained in this release are based upon what management of the company believes are reasonable assumptions, the company cannot assure investors that actual results will be consistent with these forward-looking statements. These forward-looking statements are made as of the date of this release and are expressly qualified in their entirety by this cautionary statement. Subject to applicable securities laws, the company does not assume any obligation to update or revise the forward-looking statements contained herein to reflect events or circumstances occurring after the date of this release.

The company’s actual results could differ materially from those anticipated in these forward-looking statements as a result of the factors set forth below in the “Risk Factors” section in the company’s Q3 2020 MD&A and its current annual information form.

English

English Français

Français 日本語

日本語 中文

中文